"Despite the rapid advancement in 3D printing for healthcare, challenges in quality assurance, affordability, and accessibility persist, along with the need for extensive testing of materials."

"Initial investment costs for 3D printing can hinder access, particularly in underserved communities, compounded by the lack of standardized workflows and trained personnel."

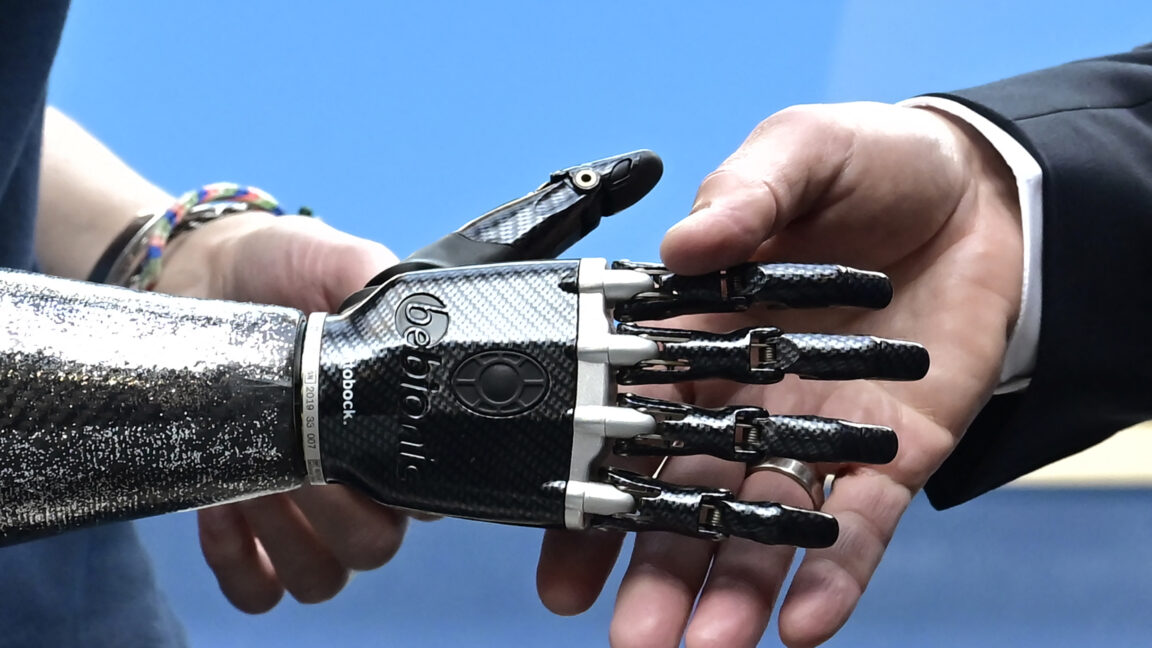

"AI-driven techniques hold promise in enhancing 3D-printed medical products, enabling personalized designs and predicting long-term performance of prosthetics through patient-specific data analysis."

"Researchers have developed a method that uses ultrasound to form liquid into 3D gel shapes inside the body, which may revolutionize drug delivery and tissue replacement."

3D printing in healthcare is advancing rapidly, but challenges regarding quality, safety, affordability, and accessibility continue to impact widespread adoption. Concerns about implant materials, particularly long-term safety, require thorough validation. While the technology can lower manufacturing costs, high initial investments deter usage among healthcare providers, especially in underserved areas. A lack of standardization and trained personnel further limits adoption. However, advancements in AI could improve product design and predict performance, while innovative techniques, such as ultrasound for creating 3D shapes within the body, promise to enhance precision in medical treatments.

Read at Ars Technica

Unable to calculate read time

Collection

[

|

...

]