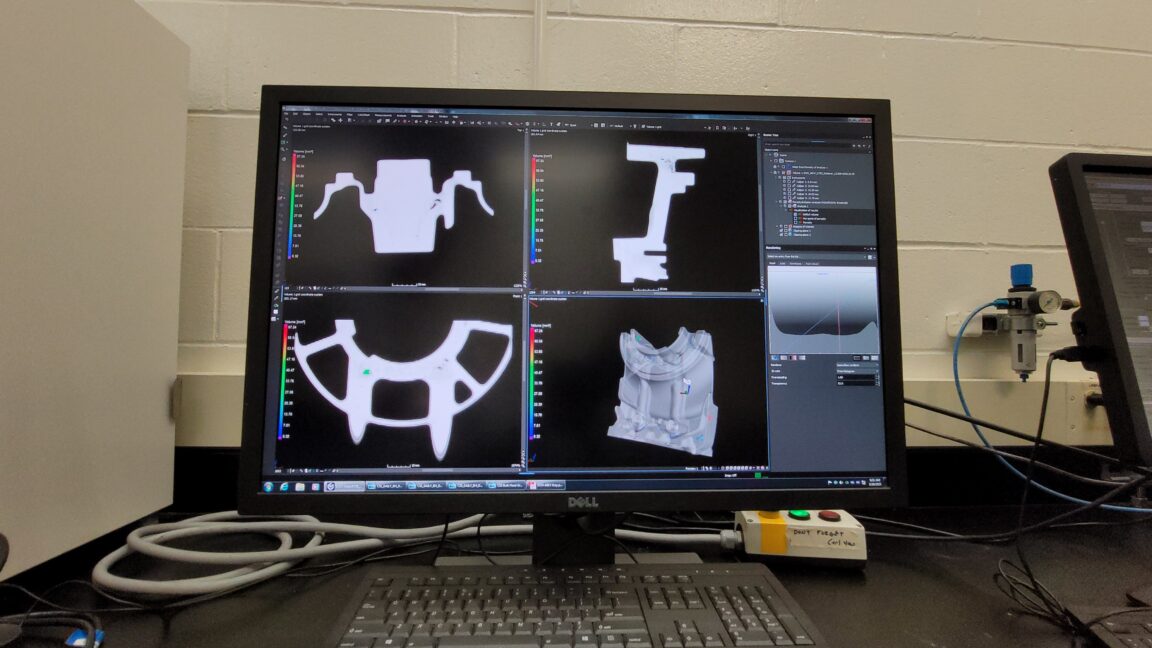

"What we're trying to do is use this tool to look at where the defects are, to change our processes so that when we build it, we don't have to deal with the defects and then the ramp plan that comes with it."

"Using CT scanners to 3D image parts during development has improved first-time quality by 90 percent and has cut development time by a third."

"The less we have to do physically, the more that we can do with math modeling, the more that we can do with simulation, the more data that you collect."

"We're a company whose been doing this for 100 years. We wish we would have collected all the data of all the things we've tried, which would then enable newer technologies like AI and other things to give us even better predictive capabilities."

CT scanning technology allows for 3D imaging of parts during development, enhancing first-time quality by 90% and decreasing development time by one-third. This improvement in quality control processes minimizes defects before production, reducing the need for labor-intensive destructive testing. Furthermore, collecting substantial data over time offers opportunities for advanced predictive capabilities through newer technologies, including AI and simulation, enhancing manufacturing efficiency. The goal is to evolve processes based on defect analysis, optimizing future development efforts.

Read at Ars Technica

Unable to calculate read time

Collection

[

|

...

]