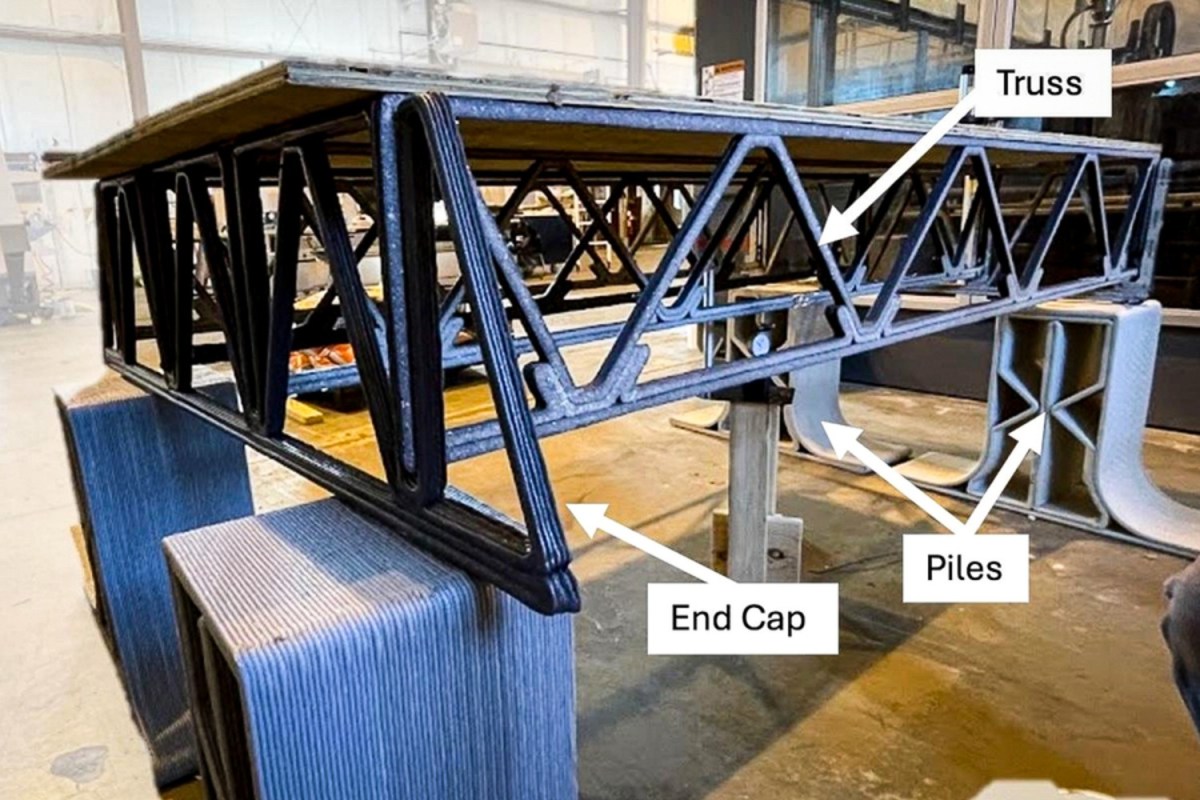

"When you think about building a house, what materials come to mind? Brick, wood and metal all come to mind; there are also some very distinctive glass houses out there. (Even if their occupants should refrain from throwing stones - though honestly, that's a good tip for indoor living in general.) A group of MIT researchers have come up with a very different way of making buildings, and it's one that also addresses an ongoing waste issue."We've estimated that the world needs about 1 billion new homes by 2050. If we try to make that many homes using wood, we would need to clear-cut the equivalent of the Amazon rainforest three times over," explained AJ Perez, who conducts his research in the MIT Office of Innovation. The title of a paper written by Perez and his colleagues - "Design, Manufacture and Testing of Structural Trusses Using Additively Manufactured Polymer Composites" - gives a sense of the solution that they have in mind."

"Using a 3-D printer, the scientists used recycled plastic to make floor trusses, then tested them to determine how much weight they could support. They found that these trusses, which weigh just 13 pounds, can support more than 4,000 pounds of weight - a number that exceeds the standard set by the U.S. government.There is one other advantage to the approach taken by Perez and his colleagues: this use of recycled plastic does not require the plastic in question to be clean. "The questions we've been asking are, what is the dirty, unwanted plastic good for, and how do we use the dirty plastic as-is?" Perez said; this looks like one encouraging answer."

The world needs about 1 billion new homes by 2050, and producing that housing with wood would require clear-cutting the equivalent of the Amazon rainforest three times over. Researchers used a 3-D printer and recycled plastic to manufacture floor trusses and tested their load capacity. The printed trusses weigh about 13 pounds yet support more than 4,000 pounds, exceeding U.S. government standards. The process accepts dirty, unwashed plastic, allowing use of unwanted plastic as-is. MIT HAUS, based in the Laboratory for Manufacturing and Productivity, has explored using recycled polymer products for housing since 2019. This approach offers a potential material solution for large-scale, sustainable housing and reduces plastic waste streams.

Read at InsideHook

Unable to calculate read time

Collection

[

|

...

]