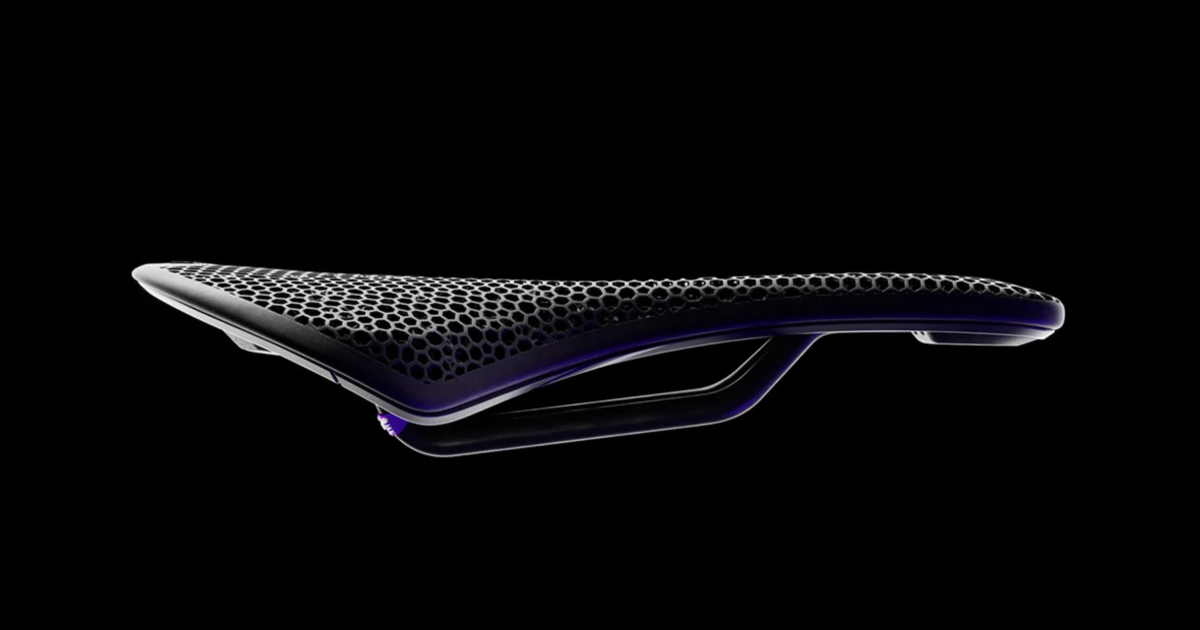

"If you've ridden a lattice-style saddles from brands like Fizik, there's a good chance Carbon's tech was behind it. The company provides the printers, resins, and production tools used to make the airy, tuned-flex structures that have quietly become one of the biggest material shifts in contact-point design for bicycles. Founded in 2013, Carbon's whole approach is built around integrating hardware, proprietary resins, and software into a single system."

"Instead of simply selling machines, Carbon often acts as a manufacturing partner-running full production batches for brands that don't want to operate their own print farms and deal with the headache of producing complex 3d printed parts at scale. This new funding isn't about survival. Carbon says it's near cash-flow positive, and the funding will go toward expanding production capacity, refining materials, and accelerating work on the next generation of printers and automation tools. That's notable at a time when other additive manufacturers have struggled, scaled back, or folded entirely."

Carbon secured $60 million to expand 3D printing production for bike components. The company supplies printers, resins, and production tools used to create lattice-style saddles and helmets. Founded in 2013, Carbon integrates hardware, proprietary resins, and software into a single system and frequently runs full production batches as a manufacturing partner for brands. Carbon reports it is near cash-flow positive. The funding will expand production capacity, refine materials, and accelerate development of next-generation printers and automation tools. The investment arrives as other additive manufacturers have struggled. Riders can expect more 3D-printed touchpoints, broader brand participation, and greater tuned comfort.

Read at BikeMag

Unable to calculate read time

Collection

[

|

...

]