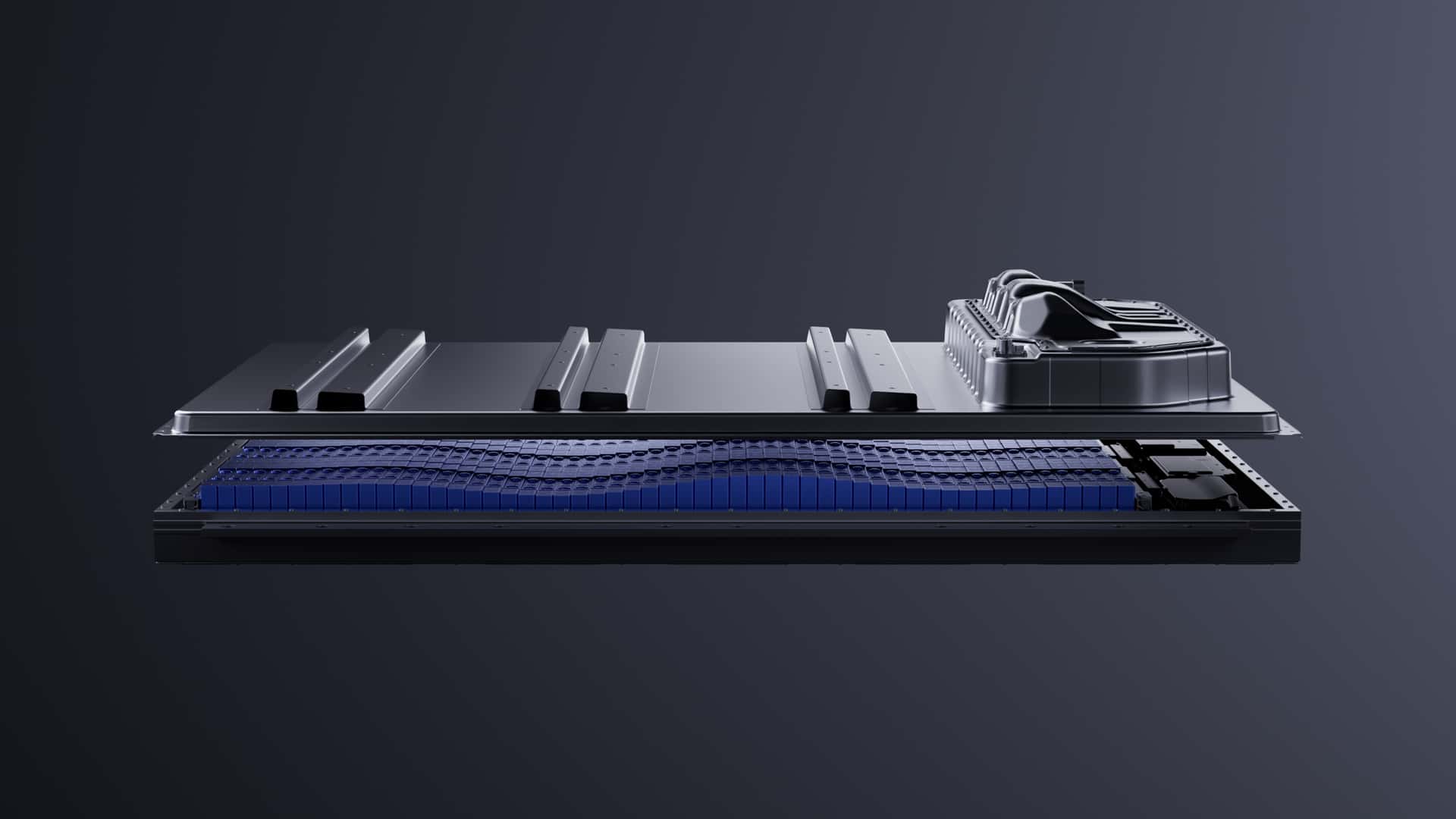

"The rollout of low-cost lithium-iron phosphate (LFP) batteries surpassed deployments of traditional nickel-based chemistries in electric vehicles in 2025 for the very first time, EV Magazine reported, citing data from the research firm RhoMotion. That marks a significant shift for the global battery industry, and its yet another sign of China's continued dominance here. For years, automakers leaned heavily on nickel-manganese-cobalt (NMC) batteries, largely because they benefited from a mature supply chain and higher energy density that delivered desirable driving range on EVs."

"But those advantages have come at a cost. Nickel- and cobalt-heavy batteries are expensive to mine, they're environmentally intensive and remain tied to controversial supply chains that involve labor and human rights violations, particularly in the Democratic Republic of Congo. As a result, battery makers have been accelerating their shift toward nickel-free chemistries such as LFP. Chinese automakers and battery companies have been leading that shift, thanks to LFP's lower costs, reduced dependence on troubled materials and a narrowing energy-density gap with NMC batteries."

LFP was the fastest growing battery chemistry in 2025, with demand increasing 48%. LFP overtook nickel-based packs to become the dominant battery chemistry globally. China spearheaded LFP adoption, followed by Europe and several Asian countries. Automakers historically favored NMC for its mature supply chain and higher energy density that provided longer driving range, especially in U.S. models. Nickel- and cobalt-heavy chemistries are costly to mine, environmentally intensive, and linked to controversial supply chains and human rights abuses in places such as the Democratic Republic of Congo. Battery makers have accelerated adoption of nickel-free LFP because of lower costs, reduced material risks, and closing energy-density gaps through design and materials optimizations. By last year, LFP accounted for more than half of global EV battery deployments.

Read at insideevs.com

Unable to calculate read time

Collection

[

|

...

]