"By and large, electric vehicle battery makers are working toward one ultimate goal: making battery packs that supply more range for less money. Better safety, fast charging, durability and recyclability are also worthy aims. But they all revolve around the same north star: maximizing range from a smaller battery at the lowest possible cost. To do that, battery makers are quickly moving away from traditional pack design."

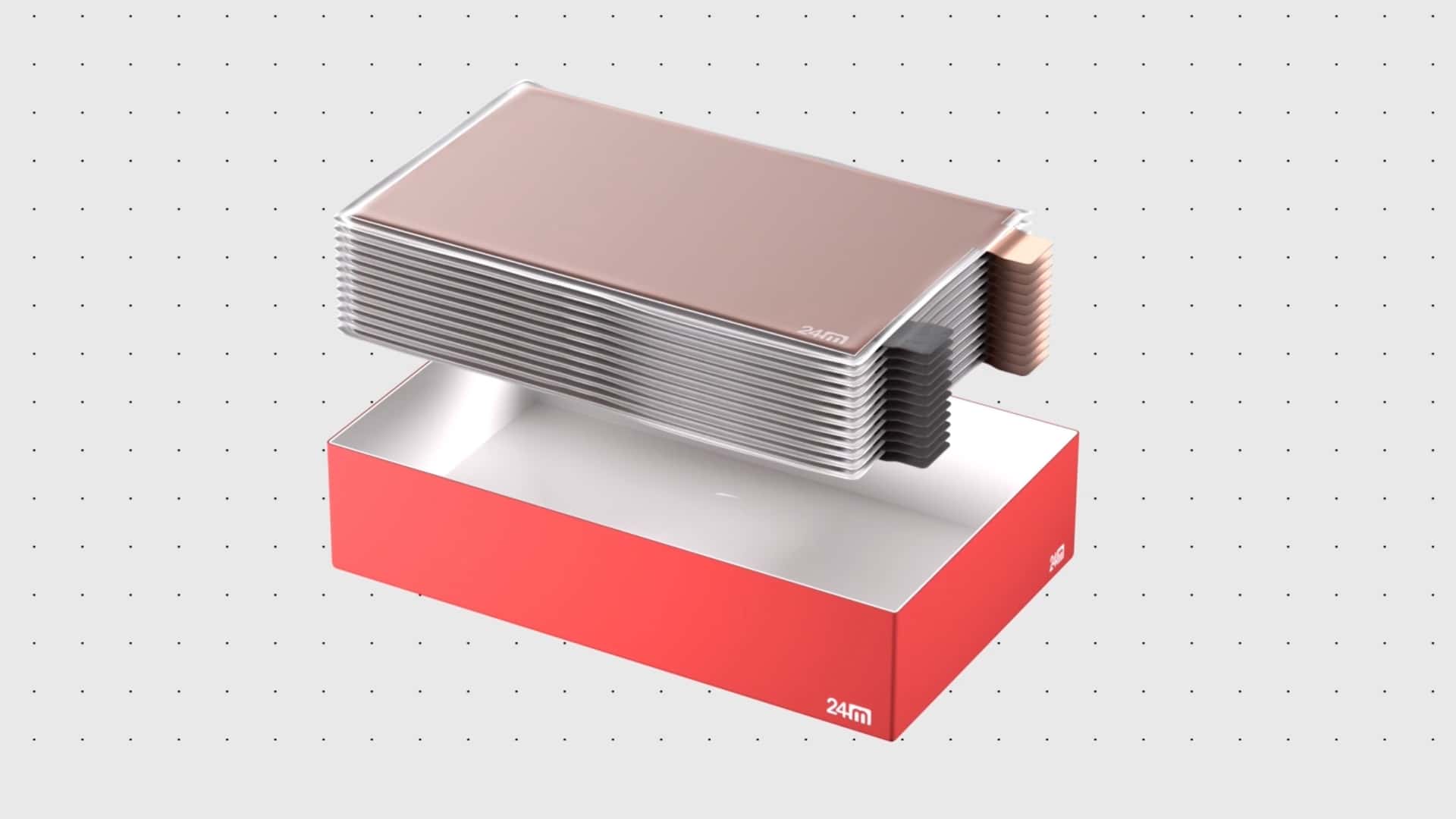

"Many now skip the step of battery modules and instead integrate battery cells directly into the larger pack (cell-to-pack), or even into the vehicle body itself (cell-to-body). Massachusetts-based 24M Technologies has taken it a step further, developing a novel electrode-to-pack (ETOP) method to enhance both energy efficiency and cost-effectiveness. The company says traditional cell-and-module designs contain a large portion of inactive and non-energy-carrying materials, like the cylindrical cell casing, for example."

24M Technologies developed an electrode-to-pack (ETOP) manufacturing platform that embeds sealed anode and cathode pairs directly into battery packs, eliminating individual cells and modules. The platform removes inactive hardware such as plastics, metals, and cylindrical cell casings, reducing material waste. Removing non-energy-carrying components increases volumetric energy density and extends vehicle range. The ETOP approach can accommodate multiple chemistries and sizes for diverse applications. The design aims to improve cost-effectiveness, safety, fast charging, durability, and recyclability by focusing pack structure on active energy-storing components.

Read at insideevs.com

Unable to calculate read time

Collection

[

|

...

]