"The replacement of state-of-the-art Ni-based superalloys in high-temperature applications to improve the efficiency of energy-conversion systems by new metallic-intermetallic materials is at present obstructed by two main limitations: (1) a lack of oxidation resistance and/or (2) a lack of ductility at room temperature (RT). No accurate predictive simulation capabilities for either of the two properties exist at present and, thus, the community still relies on disruptive observations."

"For example, Mo and most of its alloys suffer from catastrophic oxidation ('pesting') above 500 °C owing to oxidation to MoO 3, which then evaporates as a result of its high vapour pressure8. By contrast, Cr is usually considered a passivating element that forms dense Cr 2O 3 scales. However, Cr-based alloys suffer from scale spallation and nitridation (ingress of N) when exposed to air at high temperatures beyond approximately 1,000 °C (refs. 9,10)."

"Any previous successful attempt to address oxidation resistance in these alloy systems came with a substantial deterioration in ductility11,12. These attempts included the development of high Al-containing and Cr-containing complex concentrated, refractory-element-based alloys with single-phase microstructure that exhibit extreme oxidation resistance, even at temperatures up to 1,500 °C (ref. 13). However, the addition of Al promotes crystallographic ordering with a complete loss of ductility at ambient temperature."

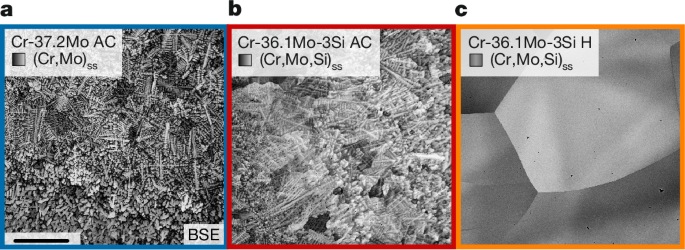

"Furthermore, alloys with high amounts of intermetallic phases containing passivating elements were introduced. These intermetallic phases, such as silicides, are brittle in nature. Particularly, Cr-Mo-Si two-phase, silicide alloys12,14 were identified to be resistant against pesting and nitridation. The protective effect of a Cr 2O 3 layer formed in these cases depends decisively on the formation of Si oxide at the interface between the outer Cr 2O 3 scale and the metallic substrate."

Replacement of Ni-based superalloys by metallic-intermetallic materials aims to improve energy-conversion efficiency but is hindered by two primary obstacles: inadequate oxidation resistance and lack of room-temperature ductility. Predictive simulation capabilities for oxidation resistance and ductility are currently unavailable, so development remains observation-driven. Mo and most Mo alloys undergo catastrophic oxidation ('pesting') above 500 °C due to formation and evaporation of MoO 3. Cr forms protective Cr 2O 3 scales but suffers scale spallation and nitridation above roughly 1,000 °C. Approaches that improve oxidation resistance, such as high Al or intermetallic additions, often induce brittle ordering or loss of ambient-temperature ductility.

Read at Nature

Unable to calculate read time

Collection

[

|

...

]