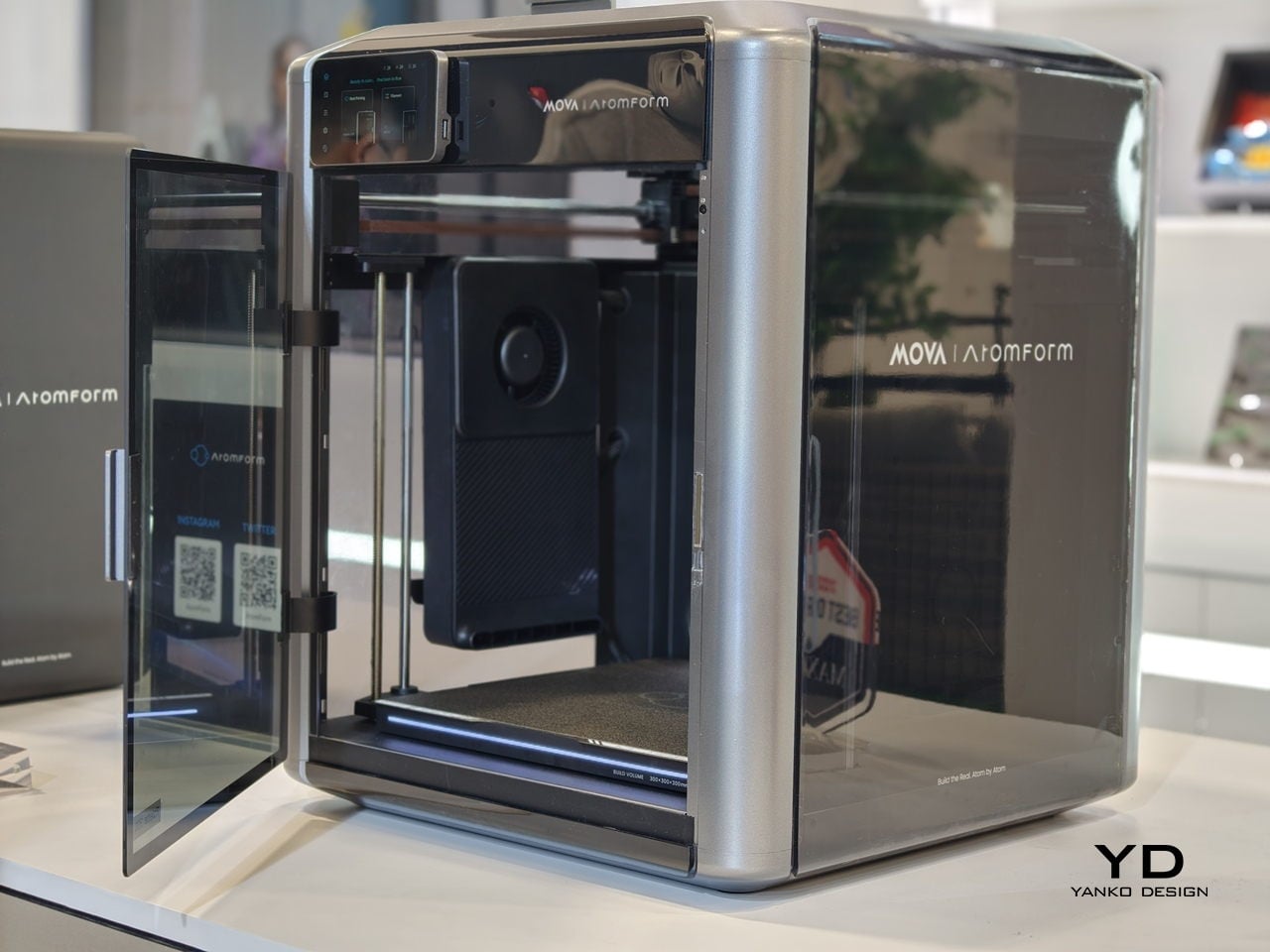

"AtomForm Palette 300 is a 12-nozzle, enclosed 3D printer built to combine up to 36 colors and 12 materials in a single print. It uses a rotating OmniElement automatic nozzle-swapping system, where each nozzle stays dedicated to one filament. AtomForm claims that the approach cuts filament waste by up to 90% by avoiding constant purging, while still hitting 800 mm/s print speeds and 25,000 mm/s² acceleration in a 300 × 300 × 300 mm enclosed cube."

"Most multi-material printers either swap entire toolheads or force a single nozzle to purge every time you change color, which costs time and plastic. The Palette 300's turret of 12 filament-dedicated nozzles can jump from one to another without constant reloading, so complex color and material changes do not feel like a penalty. That means a product prototype can have brand-accurate colors and soft-touch grips in one pass."

"The 350°C hotend and 300mm cube volume give headroom for engineering filaments and larger pieces, not just small decorative figures. A prototype sneaker with flexible soles and rigid eyelets, or an architectural mock-up that mixes translucent windows with textured facades, can happen in one job instead of several glued-together prints. That kind of integration changes how much iteration fits into a day and how confident you can be that parts will actually fit together."

AtomForm Palette 300 is a 12-nozzle enclosed FFF printer that can combine up to 36 colors and 12 materials in a single print using a rotating OmniElement automatic nozzle-swapping system. Each nozzle remains dedicated to one filament to avoid constant purging, cutting filament waste by up to 90% while reaching 800 mm/s print speeds and 25,000 mm/s^2 acceleration inside a 300 × 300 × 300 mm build volume. A 350°C hotend supports engineering filaments and larger parts. The turret enables complex color and material transitions without penalty, allowing prototypes with brand-accurate colors and mixed stiffness in one job. Reliability is enhanced by over 50 sensors and four AI-powered cameras monitoring prints in real time.

#multi-material-3d-printing #color-printing #nozzle-turret #ai-print-monitoring #engineering-filaments

Read at Yanko Design - Modern Industrial Design News

Unable to calculate read time

Collection

[

|

...

]