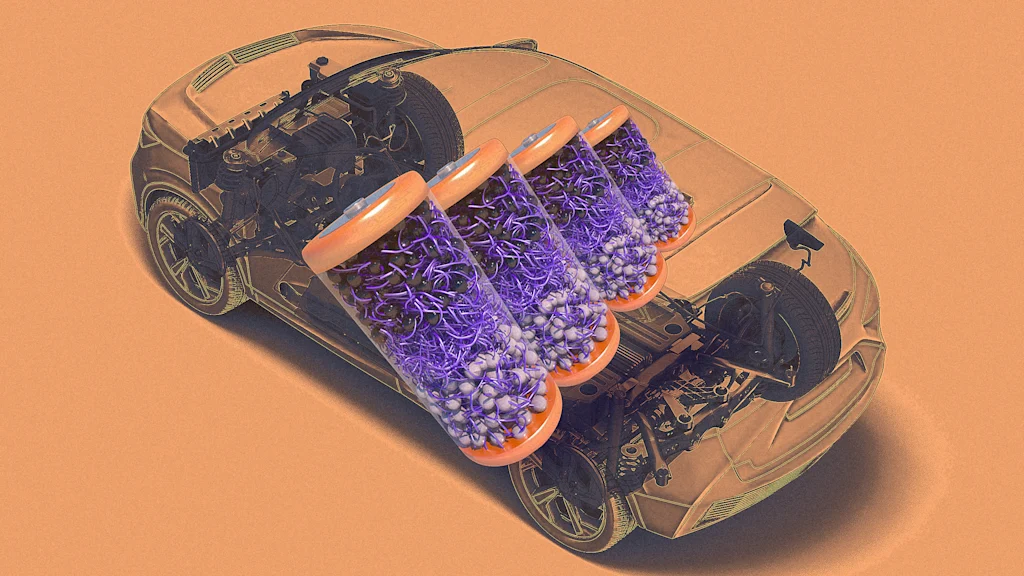

"That same year, McKinsey projects that EV battery recycling will be a $7.2 billion industry in the U.S. Currently, though, experts are still trying to find the best way to actually scale the recycling process. The prevailing strategy is a technique that essentially involves shredding EV batteries into a superfine powder -a process that has proved costly, complicated, and inefficient."

"Now, researchers at the Massachusetts Institute of Technology have published a study showing a new way to potentially bypass the shredding step altogether. According to Yukio Cho, lead author on the study and a Stanford energy postdoctoral fellow, the team has developed a new way to build a battery that makes it much easier to separate its component parts, leaving them ready for recycling."

"This year, global EV sales are expected to jump almost 25% compared with 2024. As the demand for electric vehicles soars, there's a looming concern for industry experts: figuring out the best way to repurpose the several-hundred-pound batteries that power these vehicles. According to a 2023 study by McKinsey, the global supply of EV batteries for recycling is steadily increasing and is expected to hit a whopping 7,850 kilotons in 2035."

Global EV sales are rising nearly 25% this year, increasing demand to repurpose heavy vehicle batteries. The global supply of EV batteries for recycling is projected to reach 7,850 kilotons by 2035, and U.S. recycling could be a $7.2 billion industry that year. Current recycling mainly shreds batteries into a fine "black mass," a costly, complicated, and inefficient process requiring specialized facilities. Some companies repurpose retired batteries to power data centers and charging stations. Researchers at the Massachusetts Institute of Technology developed a battery design that makes component separation easier, potentially bypassing shredding and improving recycling scalability.

Read at Fast Company

Unable to calculate read time

Collection

[

|

...

]